进入七月以来,国内多地接连高温

仅今年第27周,空调线上市场销售额就同比激增63%,线下更是暴增120%*

这种时候,有个成本不足整机3%的元件,却会成为出货的致命瓶颈Since July, many parts of China have experienced continuous high

temperatures.

In just the 27th week of this year, online air conditioner sales surged by 63%

year-on-year, and offline sales increased by a staggering 120%*

During such times, a component that

costs less than 3% of the total machine becomes a fatal bottleneck in shipment

IPM模块是什么What is an IPM

Module?

智能功率模块( Intelligent Power Module

)

IPM模块将直流电转换为精确可控的三相交流电,驱动压缩机电机实现变频调速

让空调得以降低能效↓、降低噪音↓,并提升可靠性↑Intelligent Power Module (IPM)

The IPM module converts direct current into

precisely controllable three-phase alternating current, driving the compressor motor to achieve

variable frequency speed regulation

Enabling air conditioners to reduce energy consumption↓, reduce

noise↓, and improve reliability↑

IPM的结构和要害The Structure and

Critical Points of IPM

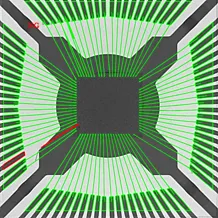

IPM为6合1封装结构,分为IGBT芯片-DBC-基板-焊料-引脚-外壳

它整合了整个压缩机需要的功率开关器件+驱动电路+保护电路

既要承受千瓦级功率的摧残,又要实现微秒级精准控制,面对的挑战可想而知IPM has a 6-in-1 package structure, consisting of IGBT

chip-DBC-substrate-solder-pins-housing

It integrates all power switching devices, drive circuits,

and protection circuits required by the compressor

It must withstand the destruction of

kilowatt-level power while achieving microsecond-level precise control, facing challenges that can be

imagined

无锡中盾科技专注工业智能在线X射线检测设备

为IPM的精密无损检测提供了解决方案Wuxi Aishield Technology specializes in industrial intelligent online X-ray

inspection equipment

Providing solutions for precision non-destructive testing of IPM

WireBonding-引线键合质量检测WireBonding - Lead Bonding Quality Inspection

问题背景:Problem

Background:

IPM模块内部通过金线/铜线连接芯片与引脚,若键合点存在偏移、断裂、弧度不足,会导致空调压缩机驱动失效。The IPM module connects chips to pins through gold/copper wires internally. If

the bonding points have offset, breakage, or insufficient curvature, it will lead to air conditioner

compressor drive failure.

解决方案:Solution:

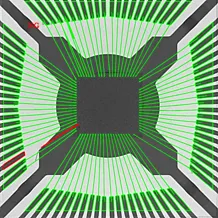

- 多角度穿透成像:通过X射线多视角透视IPM模块,清晰呈现引线键合点的三维空间位置

-

AI缺陷捕捉:AI算法自动标记键合线脱焊、弧形塌陷、交叉短路等异常- Multi-angle

penetration imaging: Through X-ray multi-angle perspective of the IPM module, clearly presenting the

three-dimensional spatial position of lead bonding points

- AI defect capture: AI algorithms

automatically mark abnormalities such as bond wire desoldering, arc collapse, and cross short

circuits

Die Bonding-芯片贴装偏移检测Die

Bonding - Chip Mounting Offset Detection

问题背景:Problem

Background:

功率芯片(如IGBT)与陶瓷基板间的银浆/焊料层若存在空洞或偏移,会引发散热不均,导致IPM模块过热烧毁。If there are voids or offsets in the silver paste/solder layer between power

chips (such as IGBT) and ceramic substrates, it will cause uneven heat dissipation, leading to

overheating and burnout of the IPM module.

解决方案:Solution:

- 分层成像技术:针对IPM的6层结构,逐层分析贴装界面。

-

数据互联:依客户实际需求接入MES、ERP、WMS等系统,实时上传检测数据。- Layered

imaging technology: Targeting the 6-layer structure of IPM, analyzing mounting interfaces layer by

layer.

- Data interconnection: Connecting to MES, ERP, WMS and other systems according to

customers' actual needs, uploading detection data in real-time.

通过智能算法+多角度成像+产线集成三位一体,无锡中盾会成为空调IPM模块质量的守护者,从源头扼杀变频空调的驱动失效风险。Through the trinity of intelligent algorithms + multi-angle

imaging + production line integration, Wuxi Aishield will become the guardian of air conditioner IPM

module quality, eliminating the risk of variable frequency air conditioner drive failure from the

source.